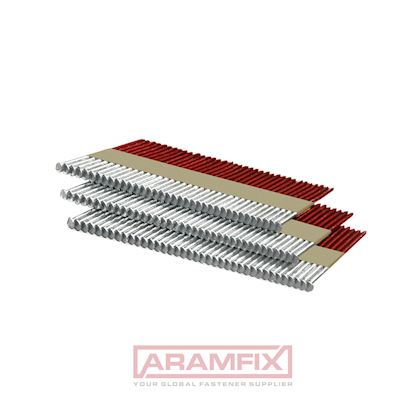

| Itemcode | BSPALC8BNHD3EM090C4EE000H |

|---|---|

| Diameter | 3.1 |

| Length | 90mm |

| Material | Low Carbon C1018 |

| Surface | Zinc Plated half red Vinyl Coated |

| Specification | BS EN 10230-1:2000 PA |

| Head | D-Hd |

| Pitch | Coarse |

| Type thread | Smooth |

| Shape tip | Diamond point |

| Packing | 2200 pcs/Box |

| Weight / 1000pcs | 5.47 |

| Weight / Packing | 12.03 |

In need of large volumes or discounted rates? Look no further! Simply send your project inquiry to quote@aramfix.com to get started. Our team of experts is ready to assist you.

BS EN 10230-1:2000 PA Paper Collated Strip Nails 35deg-Angle 3.1x90mm Low Carbon C1018 Zinc Plated half red Vinyl Coated Smooth D-Hd

Prices on request, On Request

| Origin | Exp. Del. Date |

Stock | PriceEXW /100 pcs* | Discount |

We know every detail of the market, buy directly from the manufacturer and are 100% digitally optimised without leasing cars or expensive premises. We pass this advantage directly on to you.

** 100% quality guaranteeIf something is not right, you get your money back immediately, 100%.

-

Specifications

- Purchase at the source

- Best quality/price

- Over 15 years experience

Do you have a question about this item?

Contact our sales department:

E-mail: info@aramfix.com

WORLD LARGEST DATACENTERS

DATACENTER SUPPLIER

Are you in need of top-quality construction materials for your datacenter project? Look no further than ARAMFIX! As a global supplier specializing in datacenter construction, we offer a wide range of products to meet all your needs.

From steel frame construction to security fasteners of the highest level, ARAMFIX has you covered. Our cladding with performance fasteners ensures your datacenter will be built to last and operate at peak efficiency.

Trust Aramfix to provide you with the best materials for your datacenter construction project. Contact us today to learn more about how we can help you achieve success in your next build.

HARSHEST CONDITIONS

OFFSHORE WINDPOWER

Are you in the market for top-of-the-line fasteners for your windpower projects, both on and offshore? Look no further than Aramfix - the global supplier you can trust.

Our fasteners are made from the highest quality grades, such as 1.4462, ensuring durability and reliability in even the harshest conditions.

With Aramfix, you can rest easy knowing that your windpower projects are secure and supported by the best in the business. Contact us today to learn more about how we can cover all your fastener needs.

SURFACE TREATMENTS

SPECIALS?

Are you in need of special parts with specific surface treatments for your application? Look no further than ARAMFIX! In addition to standard c-parts, we supply a wide range of specials with any surface treatment you require. Our technical team is ready to work with you to find the best solution for your needs.

Whether you need Zinc plating, PTFE coatings, or any other surface treatment, we've got you covered. Such as: Zinc plating, Zinc-Nickel plating, Zinc-Flake coatings like Geomet, Dörken, Magni, Corundum, PTFE coatings like Xylan, Xylar, Lubo lubrication, Hot dip galvanising, HDG, Sherardising, Passivating, Antifricor, Powdercoating, Mechanical Zinc, Zinc-Iron... etc. And the best part? We offer competitive prices and have a variety of options in stock, ready to meet your demand.

Don't wait any longer! Contact us today with your inquiry for specials or production volumes and let us help you find the perfect solution for your application.

INDEPENDENT LABORATORY

HARDNESS TESTING

Are you looking to ensure the highest quality standards for your products? Look no further than our hardness testing services with a state-of-the-art hardness tester.

With our expert team of technicians, we measure the Rockwell hardness (HRC) and Brinell hardness (HRB) of various materials to accurately determine their quality and durability. By using precise and reliable testing methods, we help you identify any weaknesses in your materials that could potentially lead to product failures or performance issues.

Don't leave the quality of your products to chance. Trust our hardness testing services to provide you with the most accurate and reliable results, ensuring that your products meet the highest standards for quality and durability. Contact us today to learn more about how we can help you improve your product quality with our hardness testing services.

INDEPENDENT LABORATORY

CORROSION TESTING

The best simulation of corrosion formation in practice, is achieved with cyclic corrosion tests. After lengthy research, some test methods have been developed that can actually predict product life. In addition to a salt spray phase, also using, for example, a water mist phase and a phase with regulated, low humidity, the natural corrosion process is optimally simulated. Some tests also use a phase with UV exposure followed by exposure to a temperature of -20°C. Several standards have been developed from industry for cyclic corrosion testing. Also, many automotive brands and NORSOK have developed their own test cycle.

SAE J2334, (automotive industry) / Cyclic test according to ISO 12944-9 and NORSOK (Offshore applications). Or the standard neutral saltpraytest (NSS) to compare corrosion restistance between surface treatments.

Other tests we can perform (on request) are VW PV 1210, VDA 233-102, ASTM G85 Annex 5, GM 9540P, GMW 14872, ASTM B 117 and ASTM D1735, DIN50021.

Contact us: info@aramfix.com

CONSUMABLES

TOOLS - DRILLS - ADHESIVE

Are you tired of wasting time and energy trying to mount fasteners with subpar tools? Look no further! Our company supplies the best tools and consumables for cutting, grinding, and drilling, making it easier than ever to mount your fasteners quickly and efficiently.

Our products are designed to be durable, efficient, and easy to use, ensuring that you get the job done right the first time. Whether you're working on a small home improvement project or a large-scale construction job, our tools will help you get the job done faster and more effectively.

Don't waste another minute struggling with inferior tools. Upgrade to the best in the business and see the difference for yourself. Contact us today to learn more about how our products can help you work smarter, not harder.

GLOVES - HELMETS - OUTFIT

SAFETY

Are you concerned about the safety of your workers on the job? Look no further! Our company specializes in providing top-of-the-line safety gear for all your project needs. From durable work clothing to protective gloves, eye and head protection, we have everything you need to keep your employees safe and protected on the job.

Don't take any chances when it comes to the well-being of your team. Invest in high-quality safety gear that will give you peace of mind and ensure that your workers can focus on their tasks without worrying about potential risks. Trust our expertise and commitment to safety to provide you with the best products on the market.

For any project where people work, make sure you have the best safety gear available. Contact us today to learn more about our products and how we can help you create a safe and secure work environment for your employees. Your team's safety is our top priority! Even possible with own branded and printed logo's!